Blower Drive Service Boost Chart

The blower has three speed options, plus a turbo boost button. Additional information may be needed.

To find out what pulleys to use with your combination, check out blower drive service catalog or website.

Blower drive service boost chart. They have a chart with blower size/cubic inch/pulley size to get figure boost. If you get thier tuning book it list there recomended jetting specs for a blower setup. That heat and friction causes the roots blower to be much less efficient and can’t move as much air as the screw blower.

The water pump is usually run by the alternator belt, not the blower. With the stock supercharger drive pulley, the blower could only deliver about 5 pounds of boost on the larger cylinders. Boost “leakage” to occur because the total clearance path is much longer on a larger blower.

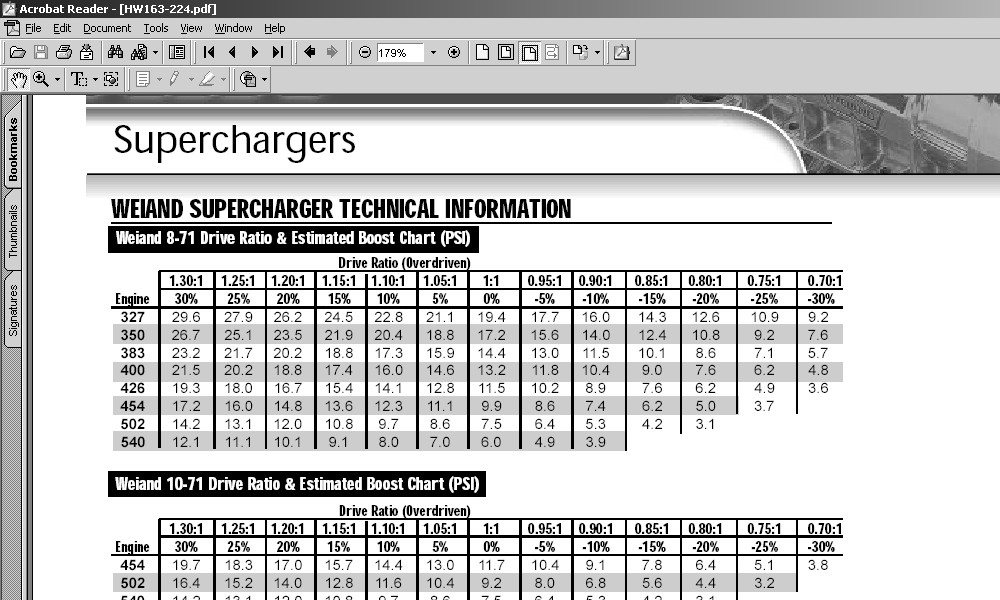

Boost is nothing more than the measure of pressure built up in the intake. The different stages and their intended uses are as follows: Most companies that sell street blower kits that go onto mildly modified motors set them up to underdrive them (top pully larger than bottom) maybe 10 to 15 % underdriven, this gives anywere from 5 to 8 lbs of boost, depending on engine.

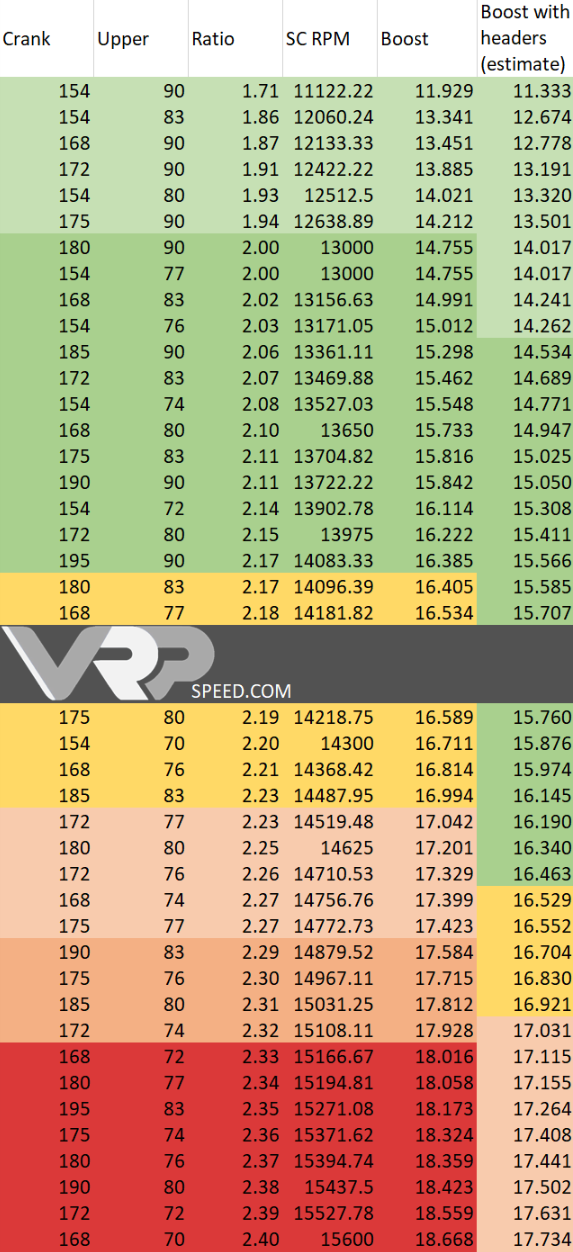

We are discussing blower speed, not engine speed, so if a blower is driven at 40% overdrive and the engine is turned to 7000 rpm, the blower is turning 140% x 7000 rpm = 9800 rpm, so everything after around 7500 and above has been a waste. The above chart shows the effective compression ratio of your engine, which combines the static compression ratio with the amount of supercharger boost. Blower pulley ratio and boost charts.

A centrifugal blower housing has a scroll The blower rpm required to move 4000 cfm on this system is 1167 rpm. Blower drive service has some good charts for drive ratios, and overall compression ratios.

We our not responsible for failures due to the improper use of blowers. An axial fan uses a propeller to draw the air into the fan and discharges the air in the same axial direction. Send email to dyer's blowers.

There is no reason why better than 10% cannot be achieved. A high helix blower will go to about 11,000 rpm before it quits making additional boost. The 11/4” 48 spline of the main shaft connects to the blower gear.

It wasn’t acceptable, but even with that, the engine spit out about the same power as a stock ls9—at only half the boost. Boost levels above 12 psi should generally be avoided even with racing fuel on a 9.5:1 motor. Many people assume a blower is making boost 100% of the time.

For carbs you can also run 2 600cfm edelbrocks. To find a snout that is right for your blower drive system, get in touch with littlefield blowers today. It says you should keep your total compression under 12.4 and with your 10.1 compression and 4lbs of boost that would put you at 12.7 which is just a little over there recommendation, so 3lbs would prob be the absolute limit.

If you are not currently going to be ordering the pulleys or belt, bds can give you a cost. If you would like bds to help with a pulley or belt configuration please supply a center to center distance between the upper and lower blower pulley as well as any pulleys or belt that you currently have. Note that for most street applications with 92 octane pump gas, you should keep your effective compression ratio below about 12:1.

Of boost in most systems, not exceeding engine speeds in excess of 7000rpm. The above chart shows the effective compression ratio of your engine, which combines the static compression ratio with the amount of supercharger boost. Dyer blowers manufactures, sells and services 471, 671, and 871 kits for chevy, ford, chrysler, mopar, dodge, plymouth, pontiac, amc, buick and oldsmobile v8 engines.

Also, hit teh search function, there are lots of good threads on blower stuff. Cross multiply 4000 times 875 to get 3,500,000 then divide that by 3000 to get 1166.67 rpm. 114 115 116 117 118

A centrifugal blower wheel draws air into the inlet of the blower housing, through the wheel, and discharges it at 90° out through the discharge of the blower housing. As long as the blower rpm can be set within 10% of the 1167 rpm, the system will be considered correctly adjusted. Dyers blowers is one of the leading manufacturers of street strip superchargers.

I looked at bds (blower drive service) website and they have a chart under the tech section that might help you. Note that for most street applications with 92 octane pump gas, you should keep your effective compression ratio below about 12:1. Littlefield blowers snouts come in a variety of sizes—including 3 7/8, 5 1/8, 6, 7 and 8 5/8.

Post a Comment for "Blower Drive Service Boost Chart"